My experiences, working with a female mechanical engineer

I hope this post finds you well.

“I came up with this position when I observed the development engineers were spending a lot of time on the manufacturing floor. I would rather have them working on the next product” said the Vice President of engineering, Dan Smith. “I started a group called Product Introduction Engineering. Basically, I am looking for a person to take the product from the developers and introduce it to the manufacturing floor. Do you think you could do this?”

“Sure.” I said, anxious for this job. I had interviewed at 3 other companies. They didn’t give me an offer and I was getting desperate. Even though this doesn’t sound like engineering work, I would do anything at this point.

“Great. I will introduce you to the manager of Product Introduction, John. Currently the department is staffed with a mechanical engineer and I think adding you, an Electrical Engineer, will make the dept. complete.”

…

“So, you’re an electrical engineer. Have you ever done this type of work before? Said John while staring at my resume.

“No.” I said, “But, I am a fast learner and can get along with all kinds of people.” Thinking that this position needs a person with an ability to communicate.

“Good. Currently I have an experienced mechanical engineer. With your addition this should make this a complete team, with the ability to handle any issues that comes up. If at any time we have an issue we can’t understand, we will have the development team to assist us. So, you won’t be alone.” I was relieved to hear that. Since I only have one year of experience under my belt. I have always admired the development and research engineers. We live in a meritocracy after all, and these people proved themselves. I am sure they would know what to do if I encounter a manufacturing issue. “I will take you back to Dan Smith and he will conclude today’s interview.”

…

“John says you would be a great addition to his team. So, I am prepared to offer you a position here as Product Introduction Engineer. The pay is $34,000 with health benefits. I need you to start as soon as we get the paperwork done. Maybe this Monday. Can you do that.” said John enthusiastically.

“Yes! I can.” With much elation, though I thought to ask for a higher salary because it seemed low, but didn’t, for fear of seeming too pushy.

On Monday John introduced me to Amy, the Mechanical Engineer. She seemed a little timid and soft spoken but was pleased to meet me. She brought me to the lab and showed me all the equipment they had. I was impressed, they had all the latest oscilloscopes and volt meters.

The company produced band printers. A 300 Line per minute chain printer, 600 and 1200 line per minute version, that was capable of printing on multiple layers with carbon paper for copies. The customers particularly liked the ability to make multiple copies. The development team is working on the next version band printer, capable of 2000 lpm. We will be introducing this.

Later that afternoon, I was alone in the lab and an older gentlemen walked in. “Hi Paul, how are you? I want to congratulate you for joining the company. I’m sure you will like working here. “

I shook hands with him and said, “Thank you sir. I am glad to be here.”

We chatted for a while. I thought he was very genuine. Then he started to talk about me working with Amy and female engineers in general. He said, “You know Paul, you will be working with Amy. Female engineers are a little different than men. There best working on the detailed aspects of the design, while men are better with the overall. I think you should know this as you will be working with her closely. She will do well working on the details”

He reached out his hand, “Once again I just wanted to congratulate you and just for you to be aware while you are working with Amy.” I instinctively gave him my hand and we shook. I was a little perturbed. When I went to engineering school, there were about 5 – 10% females. All this time I never noticed any difference. Maybe he went to a university were there were no female engineers. Although, he was older, more experienced and sounded convincing. I didn’t know what to believed. So, I brushed it off as another gender inequality issue. A hypocritical remnant from the past.

After a couple of months, our first major issue. A manufacturing line stoppage occurred. Print quality issues. Occasionally the print quality failed the customer requirements. Amy and I went to the manufacturing floor and started working on this. A print quality issue must be a mechanical problem, I thought maybe some mechanical alignment issue. We worked on this for hours while all the managers and production crew watched us patiently. At the end of the day when the employees started going home, we were no closer to a solution then when we started.

The next morning the production crew fired up some printers and discovered the issue was fixed. While Amy and I were trying to figure out what happened, Dan approached us and said, “How did you fix it?”

Amy looked at me, then Dan, and said, “We didn’t.”

Dan, looking a little perplexed then changed to relieved said, “Well whatever you did, it’s fixed. Congratulations.”

Dan walked off while Amy stared at me. “What did you do?” said Amy whispering, with eyes wide.

I was even more perplexed than Dan when I replied, “I didn’t do anything. It must have been the adjustments you made when you were checking alignment.”

“No way!”, Amy said while backing up with arms up.

A couple months later it happened again. Line stoppage, managers running around asking why, production crew telling jokes and stories while waiting. Amy and I hovering over the printers, poking, measuring, adjusting and printing test pages. Amy kept saying it was an electrical problem and of course I kept saying it was a mechanical problem. Only this time it lasted into the next day. Then once again, it was gone. Whatever Amy and I did, it worked. The managers were getting mad at us because we never could say why or what effected the print quality or how it can be fixed.

Third times a charm? That’s what they say right. Not this time. Now everybody was asking questions demanding answers as to why this is happening. One manager came by and reminded us that every time a line stoppage occurred, we were losing thousands of dollars. He puts his hands in his pockets with eyes squinting at us, as he walked away.

This was the time I thought I should get help from the experts, the designers, since they know the product better than anyone else. I went to see one of the developer engineers, Jack. I sat down in the chair in front of his desk. He looked at me like he knew why I was there. I proceeded to tell him the manufacturing 1200 lpm printer was having print quality issues and they shut down the manufacturing line. He proceeded to get his cigarettes and lighter. He lighted up, lifted his left shoulder while moving his head to the left, exhaled and said, “We are aware of this problem.”

Choking from the smoke I said, “Can you give me some advice how to go about solving this?”

Jack, looked down, put out his unfinished cigarette, leaned back in his chair. “Go talk to Peter. He’s the Chief Engineer, he may have a better understanding of what to do. … Personally, I don’t know what causes it.” He proceeded to stand as his way to indicate this discussion was over and I should leave. I said thanks and proceeded to Peters office.

Peter stared at me as I walked into his office. Like he knew I was coming. Even though he didn’t smoke, he did lean back into his chair, just like Jack did. “Paul.” He said with a confidant sounding tone. “I see you have been working on the print quality issue. I assure you; we have been working on this problem for some time now. Why don’t you check with the techs in the development lab? They might have some clues.”

As I was walking down the hall toward the development lab, I could see the techs stopped working and waited for me to arrive. The expressions on their face’s said it all. “We don’t know either”, they said. I didn’t understand why they had no idea what was causing the issue. I thought they were the experts.

Not knowing what to do, I go back down to the floor and start working on one of the printers, while everyone else was chatting, joking, intermixed with some yawning.

I took the skins off the printer to examine the platen alignment, hoping it was a mechanical problem. I poked my head into the printer. Then all of a sudden, Amy came charging over to me, “Paul, Paul, I got it, I got it.” I pulled my head out of the printer and looked up, “It’s the humidity.” Amy said with a supreme confident voice. I pondered a second while Amy turned and pointed to the far wall up near the ceiling. And there installed was a humidity sensor. This was in 1985, so this unit was an analog sensor. It had a drum that turned maybe a degree every hour while a pen recorded the humidity. Then it hit me. This was genius idea, thinking outside the box. No detail here just good dam engineering investigative work, very impressive?

Paper absorbs moisture. When it’s dry it is thin, very slippery and can produce a lot of static electricity. When it is moist it’s thicker, rougher to the touch and less likely to produce static electricity, although it can produce it. The printer had print quality issues when it was extremely dry, low humidity. This was rare and that’s why it didn’t happen that often and no one could make the connection, not even the experts. But Amy did. This required seeing the big picture and thinking outside the box. Who would have thought that the humidity would cause the print quality issues? The experts didn’t. I learned a lot from Amy and will never doubt. There really is, no difference.

Note: This is a true story. Names were changed.

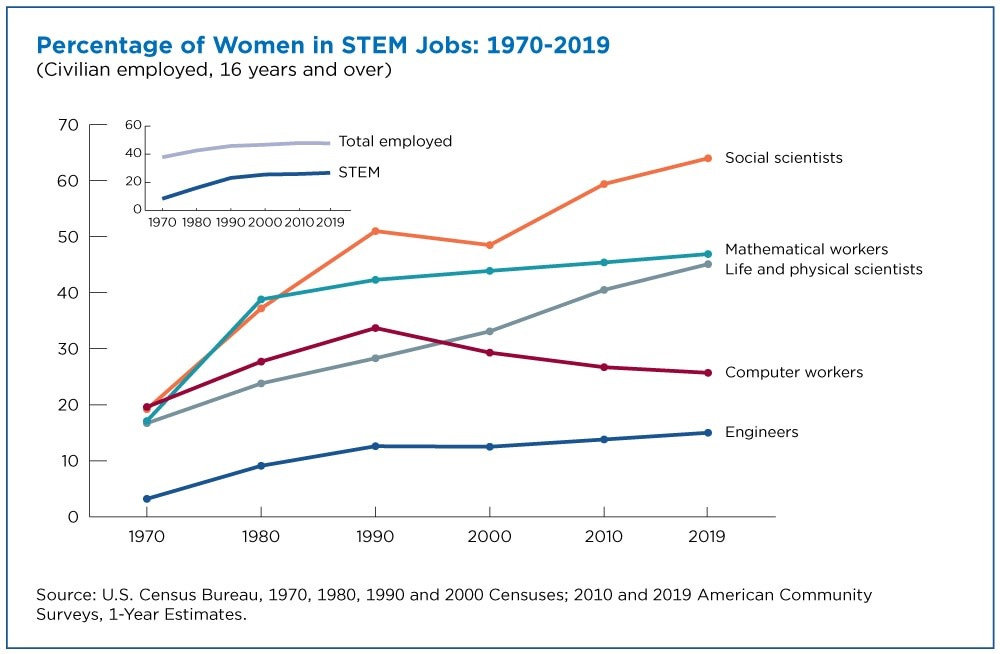

Here are some female engineering statistics:

Percentage of female engineers in 1966 was 0.4%.

Percentage of mathematics and computer science degrees in 1985 was 39.5% and declined to 25.3% in 2008.

Master’s degrees in engineering, increased from 0.6% in 1966 to 22.9% in 2008.

Doctoral degrees in engineering during the same period increased from 0.3% to 21.5%.